PTPA Middle East is a leading group in the field of design, production and supply of valves for Oil and Gas, power generation, refining, chemical and other industries.

Today, PTPA ME’s strong market position is due to customer trust, which is based on longstanding traditions of high quality production, highly qualified team coupled with their commitment to excellence in providing best solutions for our customers, and flexible approach in promotion of products and services.

PTPA Middle East FZC is located in Hamriyah Free Zone, Sharjah, United Arab Emirates.

PTPA ME manufactures a wide range of Ball Valves, Gate Valves, Shut-off and Check Valves in full compliance with international standards. The PTPA Middle East team has extensive experience in design and manufacturing of valves for oil, gas and energy industries.

Operation planning is executed through the ERP system (NOTYO) where the factual status of all processes is tracked for each order with detailed information for every item and its component.

100% traceability of each component with reference to a particular Purchase Order and dispatch schedule as per Contract terms and conditions.

1. Details of every order and its items are uploaded in the NOTYO SYSTEM for tracking purposes of the manufacturing process in accordance with the internal deadlines and project execution schedule.

2.Every new process is scheduled and tracked per PRODUCTION ROUTING LIST with bar-codes for every component. It enables to update automatically the information in the NOTYO system.

3. System allows to track and store Material Test Reports for each component with reference to specific Purchase Order including external certificates and reports of inhouse tests.

valves

critical applications

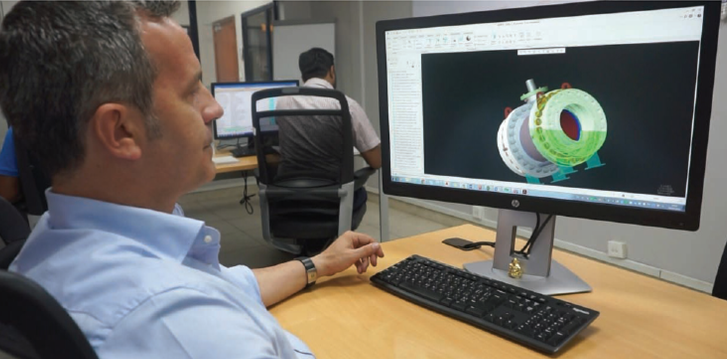

ENGINEERING CENTRE

requirements

REFERENCES

customers around the globe

Our products are designed in accordance with customer specifications and process duties, within the provisions of the main international standards (ANSI, ASME, API or PED as applicable), combining strictness in engineering and extent in flexibility.

Our engineers work with the aid of the 3-D design programs, integrated with Stress and Deformations simulators.

The simulation of every structural aspect, controlling material stress and deformation, reaction forces and residual strains, is the starting point of our design.

Positive material identification including visual and dimensional check, chemical composition analysis, tensile, hardness and impact testing and metallographic surveys at the ISO 17025 accredited laboratory.

Non-destructive examination procedures including visual and dimensional process inspection as per MSS SP-55, dye penetrant, magnetic particle, ultrasonic and radiographic testing as per ASME codes, acoustic emission diagnostics, vacuum tightness testing on fugitive emission. All testing is performed by ISO 9712 qualified personnel.

Acceptance testing. Pressure testing is held according to API 6D, API 598 or Client’s standard with possibility of direct witnessing either by C clients representative or a Third Party Inspector.

We develop CREATIVE solutions that are customer led and specifically engineered to help our customers achieve operational efficiency